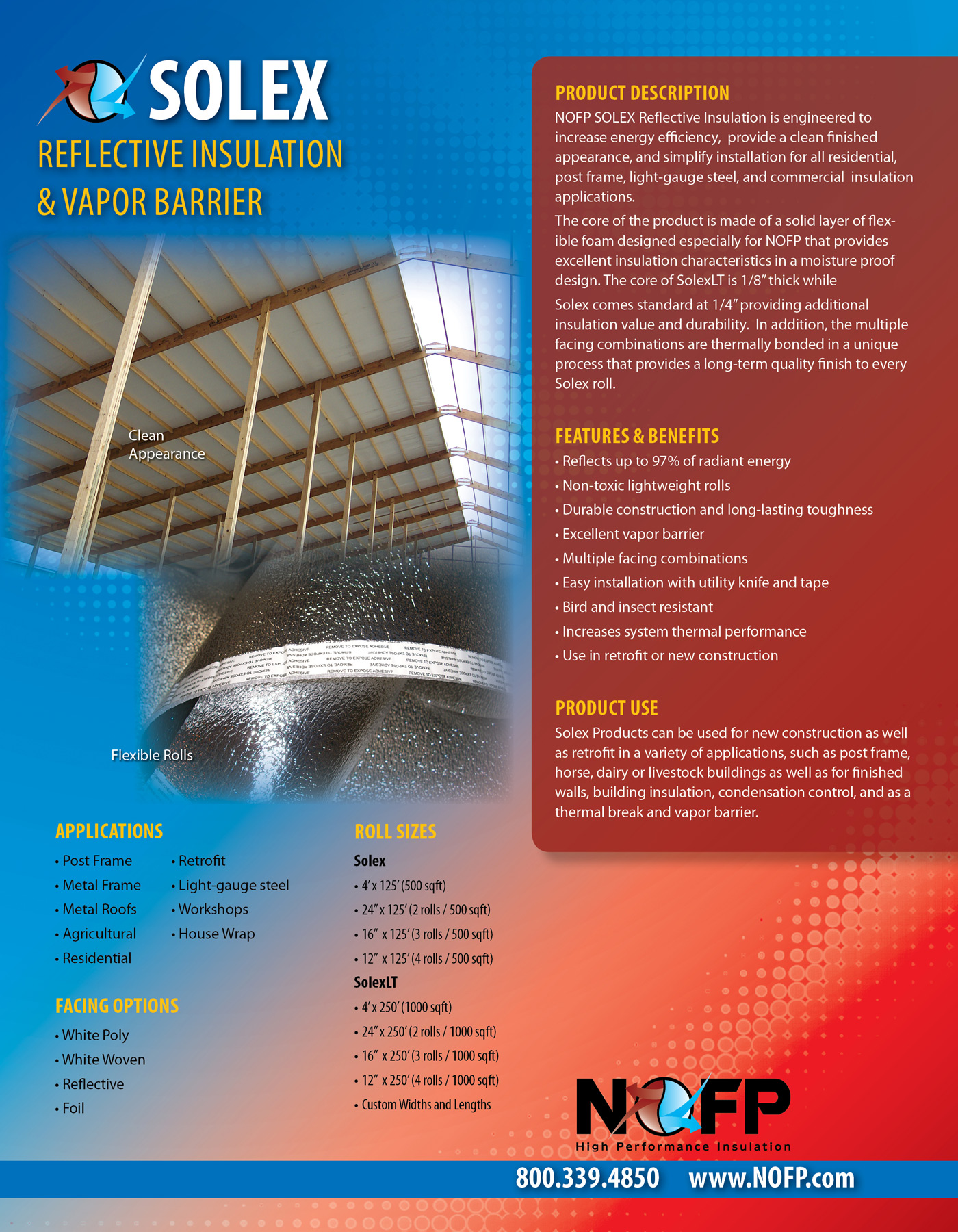

Roof Systems uses NOFP SOLEX Reflective Insulation system. It is engineered to increase energy efficiency, provide a clean finished appearance and is simply installed on all residential, post frame, light-guage steel, and commerical insulation applications.

The core of the product is made of a solid layer of flexible foam designed especially for NOFP (Northwestern Ohio Foam Products Inc.) that provides excellent insulation characteristics in a moisture proof design. The core of SolexLT is a moisture proof design. The core of SolexLT is 1/8″ thick while Solex comes standard at 1/4″ providing additional insulation value and durability. In addition, the multiple facing combinations are thermally bonded in a unique process that provides a long-term quality to every Solex roll.

SOLEX Spec SheetApplications

- Post Frame

- Residential

- Metal Frame

- Retrofit

- Metal Roof

- Workshops

- Agricultural

- House Wrap

Facing Options

- White Poly

- White Woven

- Reflective

- Foil

Features and Benefits

- Reflects up to 97% radiant energy

- Non-toxic lightweight rolls

- Durable construction and long lasting toughness

- Excellent vapor barrier

- Multiple facing combinations

- Easy installation with utility knife and tape

- Bird and insect resistant

- Increases system thermal performance

- Use in retrofit or new constuction

Product Use

Solex Products can be used for new construction as well as retrofit in a variety of applications, such as post frame, horse, dairy or livestock buildings as well as for finished walls, building insulation, condensation control, and as a thermal break an vapour barrier.

Roll Sizes

Solex

4′ x 125′ (500 sq ft)

24′ x 125′ (2 rolls / 500 sq ft)

16′ x 125′ (3 rolls / 500 sq ft)

12′ x 125′ (4 rolls / 500 sq ft)

SolexLT

24′ x 250′ (2 rolls / 1000 sq ft)

16′ x 250′ (3 rolls / 1000 sq ft)

12′ x 250′ (4 rolls / 1000 sq ft)

Core

Solex 1/4″ moisture proof polyethylene

SolexLT 1/8″ moisture proof polyethylene

Surface Reflectivity

Foil up to 97%

White N/A

Reflective up to 94%

Flame Spread/Smoke Spread – ASTM E84

White Poly or White Woven Exposed 0/15

Reflective Exposed 0/10

Foil Exposed N/A

Usable Temperature 200° F / 93° C

Warning: Solex products have been ASTM E84 tested. It is not recommended that Solex be exposed to possible ignition sources or open flame during shipping, storage or installation. Caution: Aluminium foil conducts electricity. Care should be taken around electrical sources and overhead power lines.

System Thermal Insulation R-Value

Solex Horizontal 1″ x 5.5″ airspace 5.8 / 9.5

SolexLT Horizontal 1″ x 5.5″ airspace 5.4 / 9.1

System R-Values were tested as part of a 1″ airspace assembly behind vinyl siding and as part of a 2 x 6 full wall cavity with OSB and drywall. The R-Value of reflective foil insulation is application specific. Please contact your representative for a complete table of System R-Values based on your insulation method.