Most concrete roofs are constructed using reinforced concrete which is known to have capillary tracts. Depending on the designed strength, density and installation techniques, the number of pores can vary. These pores are interconnected within the concrete and water will penetrate through such capillary tracts aided by osmotic effect. Concrete is known to be inherently weak in tension; cracks and voids can also form due to thermal expansion, contraction and shrinkage. As a result, water will seep through these voids. Therefore, waterproofing is required to keep the roof water-tight since they are exposed to weather.

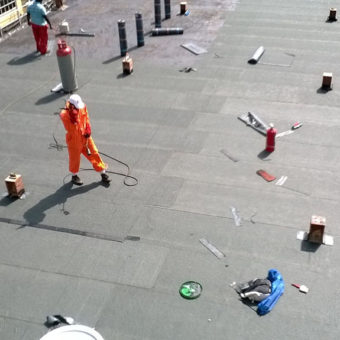

Roof Systems uses pre-formed sheet polymer-modified bitumen waterproofing membranes, (imported from Vetroasfalto, Italy), produced in rolls and applied by heat, which acts as a protective layer against water seepage. It also has a granule ceramic overcoat giving the membrane added protection against heat and UV rays. Waterproofing membranes are most commonly used for concrete decks, roofs, walls (against the earth) and foundations. It can be applied in single, double and triple layer depending on the builder. The waterproofing membrane is considered to be the most important component of a concrete roofing system as it serves the main function of keeping water out of the building.

See below for downloadable pdfs

- Technical guide solutions regarding various applications

- Detailed instructional guide to laying of the waterproofing membranes

- Specifications chart for Vetroaslfalto polyer-modified bitumen waterproofing membranes