A traditional purlin strictly by definition is a horizontal structural member in a roof. Purlins traditionally support the roof deck / cladding / sheeting and are in turn supported by the principal rafters / steel beams etc.

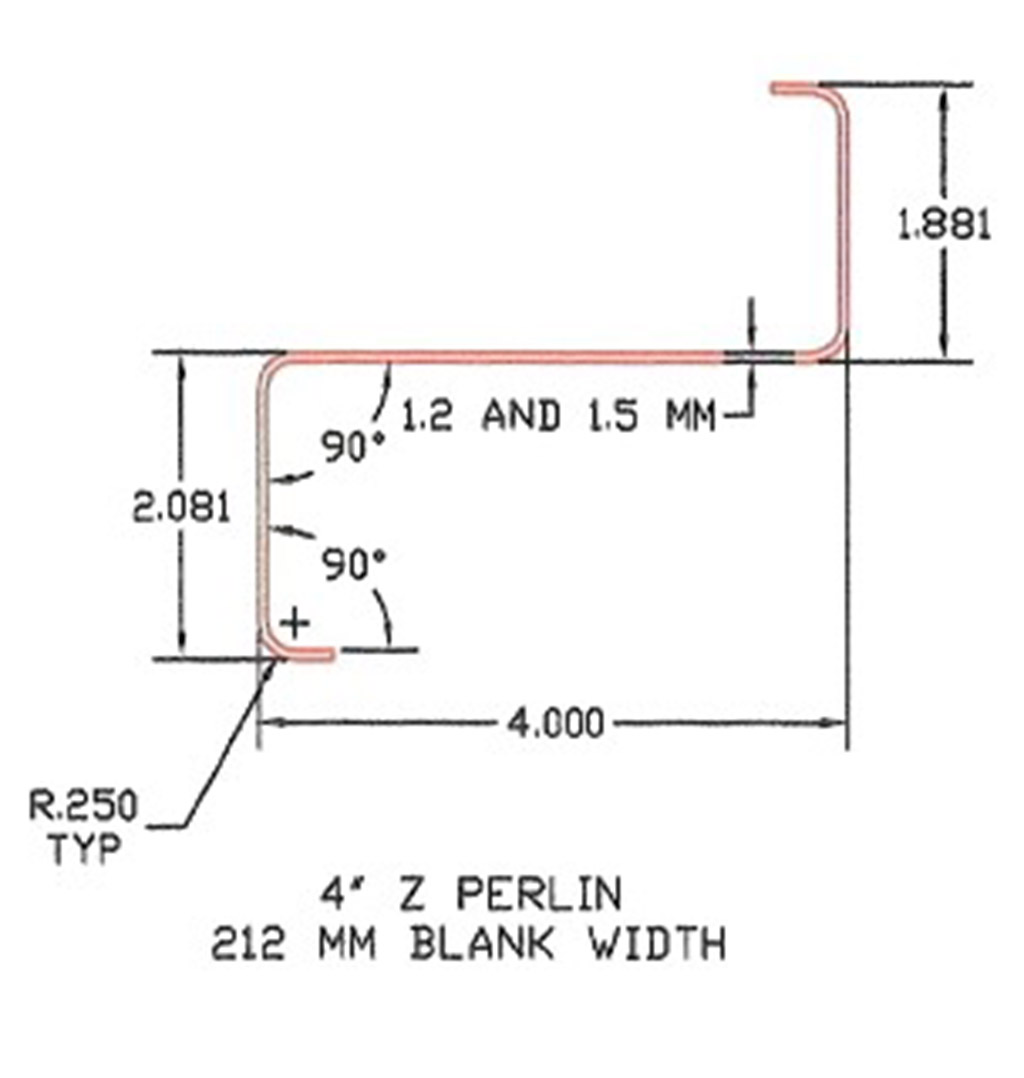

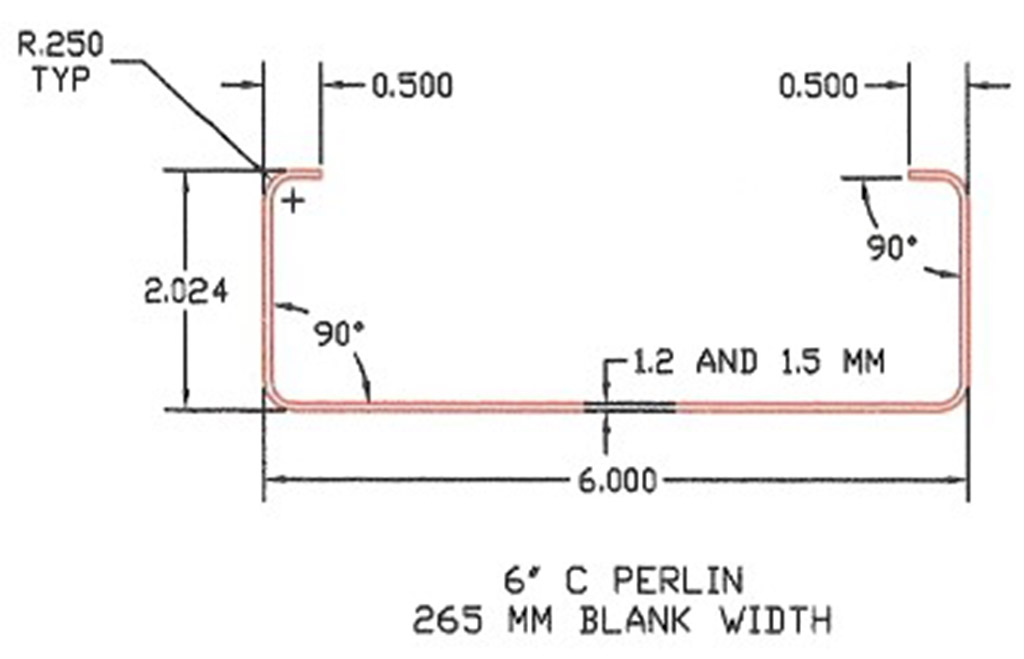

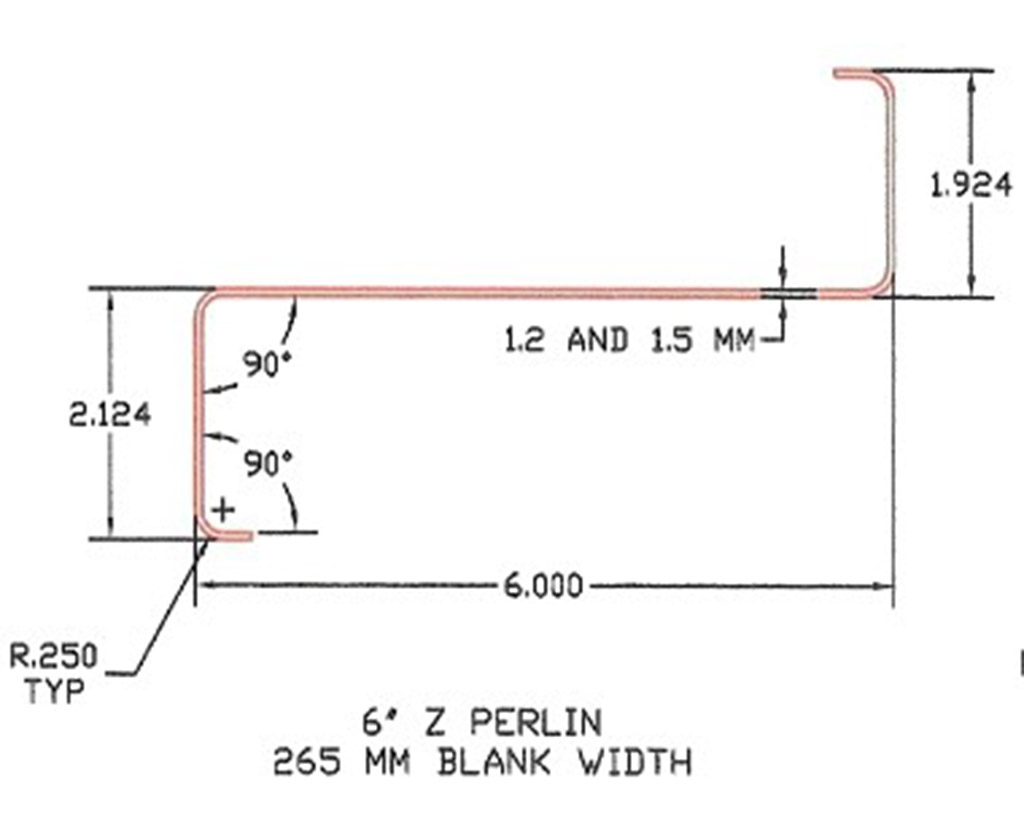

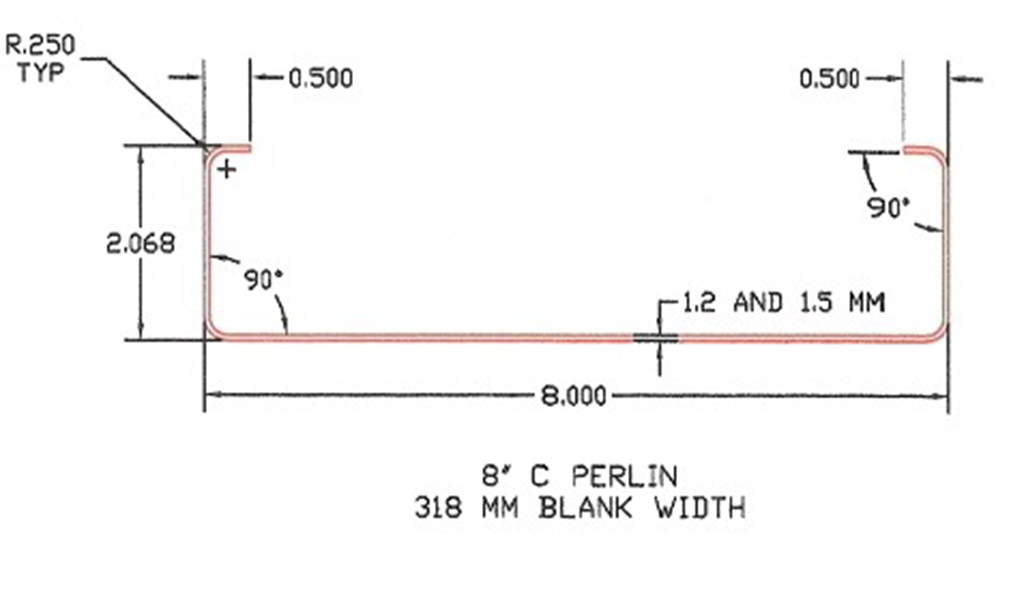

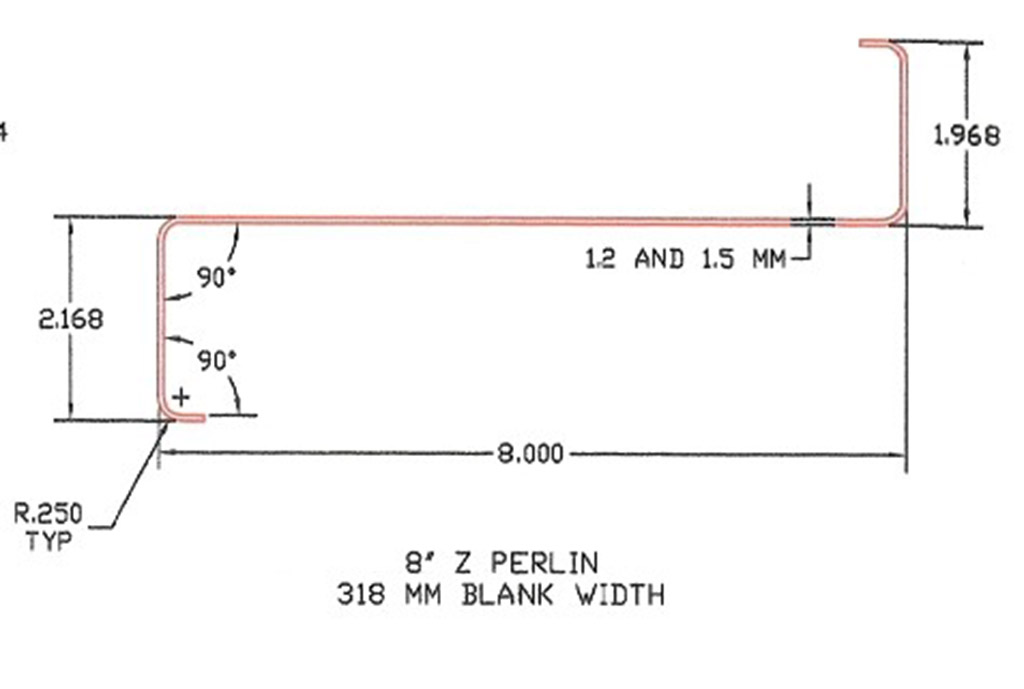

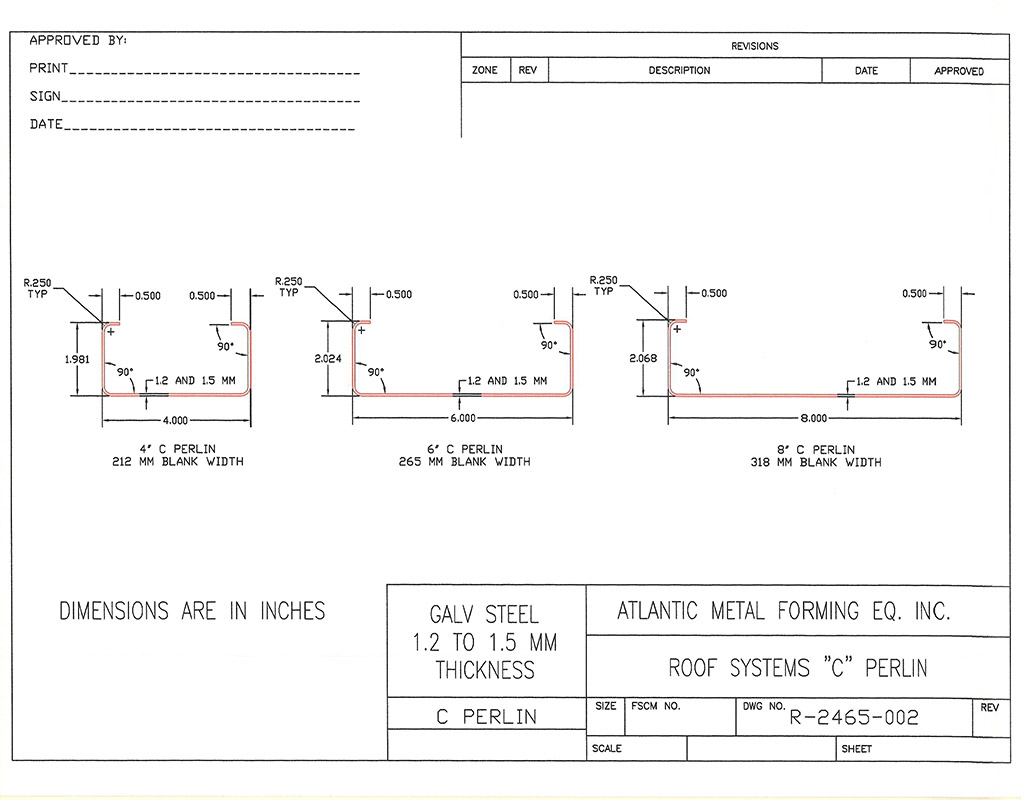

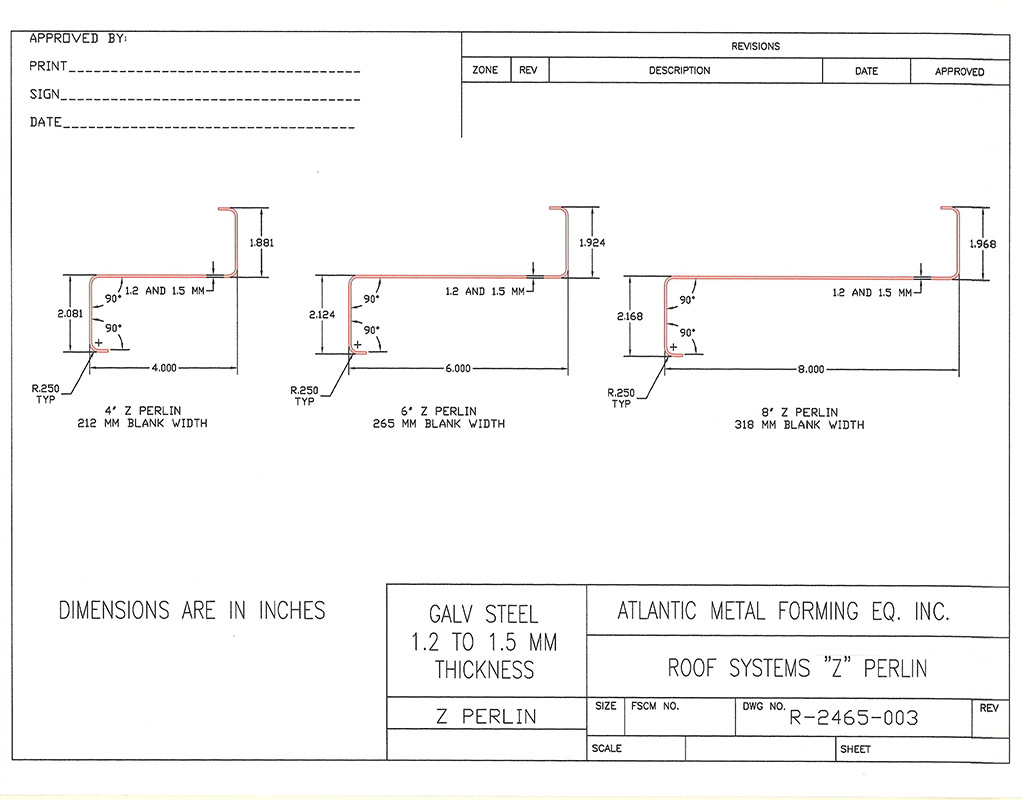

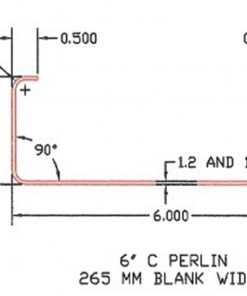

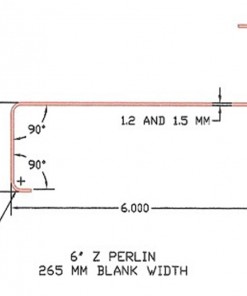

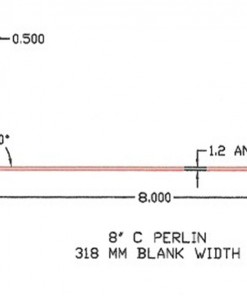

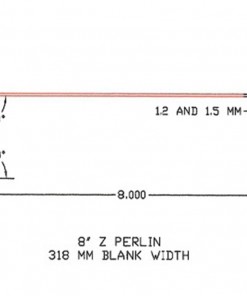

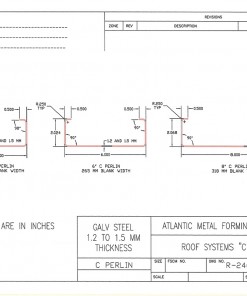

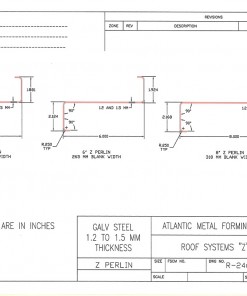

In the past, the majority of roof structures were of wooden construction but over the past 15 to 20 years there has been a vast shift away from wood to metal (mainly steel) roof construction. The typical roof structure now consists of steel “I” beam rafters placed approximately 10 feet (this varies depending on purlin size and other variables) apart with either 4″, 6″, or 8″ lightweight steel purlins installed horizontally across the rafters. In some instances, either 6″ or 8″ “C” purlins back to back can be used as rafters. This is known as a lightweight steel system. Hat channels can also be used as a purlin where a lower profile is required or where the cover system requires closer purlin spacing thus making standard “Z” or “C” purlins overly expensive. The advantages of using a steel structure over a wooden one are numerous and a few of them are listed below:

- Steel is generally cheaper than wood construction

- Steel is recyclable and thus “greener” than wood

- Steel structures can be assembled quicker than wood

- Steel is lighter than wood structures of the same size

- Steel is not affected by termites or other insects that feed on wood

- Steel can be expected to last much longer than wood in most applications

- Steel has greater fire resistance than wood